“I’m getting real world experience and that’s the thing that set me over.”

Tyler Bylsma ‘17 was playing on both the offensive and defensive lines on the Calvin High School varsity football team when the most unfortunate of circumstances altered the course of his life.

During a game in his junior year, Bylsma broke his wrist.

The injury ended both his football and wrestling seasons that year but it also spurred a medical journey that has inspired him to this day. In the days following his injury, Bylsma got an MRI, underwent ultrasound therapy and eventually needed surgery to implant screws into his wrist.

“Going through all of that got me interested in the medical field and how machinery can diagnose and heal people,” Bylsma said. “That’s what got me interested in Biomedical Engineering.”

Bylsma was healed and ready to wrestle and play football in his senior year of high school but his experiences from the previous year helped guide his decision to pursue engineering in college.

“I had two cousins who graduated from Kettering and they both work at General Motors right now. One of them really convinced me that I should go to Kettering because of the co-op experience,” Bylsma said. “I’m getting real world experience and that’s the thing that set me over.”

Bylsma left the Grand Rapids, Michigan area for the first time in his life to pursue a Mechanical Engineering degree at Kettering while completing his co-op at Boston Scientific in Spencer, Indiana.

During his first co-op term, Bylsma was conducting tests to validate a medical device process. His second rotation was assisting with the development of a manufacturing process. The device he worked on - LithoVue, a digital flexible ureteroscope - is now on the market in the United States. He also worked on SureDrive, a steerable ureteral stent deployment device that is now popular in Europe.

“We only want to make good products,” Bylsma said. “We validate the process to make sure we only make good parts. We don’t want the surgeon to take out a piece of equipment that isn’t working. We need to make sure everything is manufactured correctly.”

Bylsma spent the next three terms at Boston Scientific working on a confidential thesis project that involved creating a new tool for doctors to heal patients with kidney stones. In fall 2016, Bylsma brought his work experiences to Kettering when he engaged in an independent study alongside Dr. Patrick Atkinson in the Mechanical Engineering department. For this study, Bylsma wanted to design and produce a prosthetic hand that responded to biological signals.

“I thought it was a good project because I would cover areas of Biomedical Engineering such as Biomechanics for the hand, and bio-signal processing in more depth,” Bylsma said. “Your body sends out signals, I used those signals to turn the motor of the hand on and off.

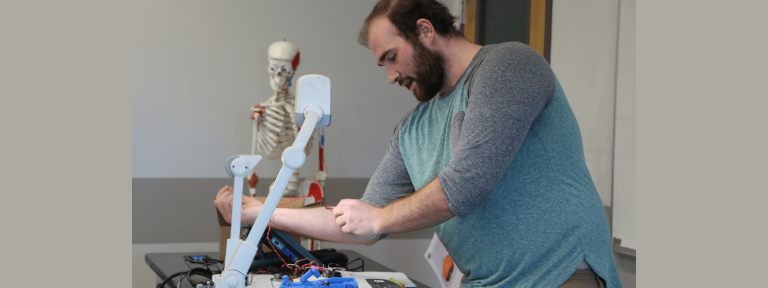

Bylsma demonstrated the results of his independent study in Mech 350 Introduction to Bioengineering in February 2017, a class he had also taken the previous year which further cemented his desire to pursue Biomedical Engineering. After attaching sensors on his elbow and forearm, Bylsma showed how a response from his arm resulted in a movement in the prosthetic hand.

Mech 350 is the first of five required classes for the Biomedical Engineering concentration at Kettering. Atkinson describes the concentration as a “holistic” approach to the field as it provides a strong foundation in both Engineering and Biology. For example, students are able to take classes related to the mechanics of the body while also completing coursework in the Crash Safety Center on campus to see how the body responds to trauma in extreme circumstances.

“The curriculum complements the experiences that our students have in their co-op positions and the combination of the two sets them up for future success,” Atkinson said. “Tyler has an enormous amount of knowledge of the biomedical industry which will provide him with multiple career opportunities in the medical and engineering fields.”

Bylsma will graduate in June 2017 and is currently in the process of applying to graduate schools in Biomedical Engineering. Whether in industry or in higher education, he ultimately hopes to work on the potential therapeutic properties of ultrasound as a non-invasive surgery tool.